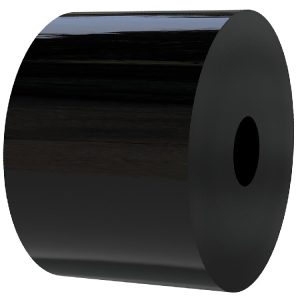

| Product | Stainless Steel strip |

| Origin | POSCO,JISCO,TISCO,LISCO,BAOSTEEL |

| Grade | 304/316L |

| Surface | No.1,2B,No.4,BA,8K,Hairline |

| Standard | AISI,ASTM,JS ,EN, DIN,GB |

| Technical | Hot Rolled,Cold Rolled |

| Thickness | 0.3mm to 5mm (Cold Rolled Process) 3.0mm to 35mm (Hot Rolled Process) |

| Width | 10-1500mm |

| weght | 1- 20tons |

| Appli icatio n | Kitchenware, Tanks, Food Pocssin, cutlery, construtin, household hardware, surgical instruments, major appliances, industrial equipment and asan autom ative and aerospace structural allyly Art Decorati on, Partiti on Screen, Door, Elevatar, Lift ,wall Decoration, Cover Panel, Table ar decorative surface Dinner set, Kitchen ware, Owner frame of security door, Auto vn-ipe, Vacum cup Clan buket water sink and s0 on |

| Package | In bundles, packed with Water proof paper and wooden pallt. To be packed strongly avaid damage during transprtation, and can be also according to the regulations and customer’s requests. Furthermore, products packages also are tagged clear on the outside for easy identifiction of the product and qual ity informati on. |

technical parameters for 316

1. **Chemical Composition**:

– Chromium (Cr): 16-18%

– Nickel (Ni): 10-14%

– Molybdenum (Mo): 2-3%

– Carbon (C): Maximum 0.08%

– Manganese (Mn): Maximum 2%

– Silicon (Si): Maximum 1%

– Phosphorus (P): Maximum 0.045%

– Sulfur (S): Maximum 0.03%

– Iron (Fe): Balance

2. **Mechanical Properties**:

– Tensile Strength: 515 MPa (74,900 psi) minimum

– Yield Strength (0.2% offset): 205 MPa (29,800 psi) minimum

– Elongation (% in 50mm): 40% minimum

– Hardness (Brinell): 217 maximum

3. **Physical Properties**:

– Density: 8.0 g/cm^3 (499 lb/ft^3)

– Melting Range: 1370-1400°C (2500-2550°F)

– Electrical Resistivity: 74 µΩ·cm at 20°C (68°F)

– Thermal Conductivity: 16.2 W/m·K at 100°C (212°F)

4. **Corrosion Resistance**:

– Excellent resistance to corrosion in various environments, including seawater, acidic solutions, and chloride-containing environments.

– Resistant to pitting and crevice corrosion.

5. **Heat Resistance**:

– Maintains strength and corrosion resistance at high temperatures.

– Suitable for applications involving elevated temperatures up to 870°C (1600°F).

6. **Fabrication**:

– Easily machined, welded, and formed using standard techniques.

– May require post-weld annealing to restore corrosion resistance in welded structures.

7. **Applications**:

– Marine equipment and hardware

– Chemical processing equipment

– Pharmaceutical and medical devices

– Food and beverage processing equipment

– Architectural components

– Oil and gas industry components

– Heat exchangers and condensers

These parameters may vary slightly depending on specific product standards, manufacturing processes, and product forms (e.g., sheets, plates, bars, tubes).